Rotary (Wankel) Engines

Rotary engines, commonly known as Wankel engines, are a

distinctive type of internal combustion engine that differ significantly from

traditional piston engines. Named after their inventor, Felix Wankel, these

engines offer a compact, lightweight design and have been used in various

applications, from sports cars to aircraft. This article explores how rotary

engines work, their advantages, challenges, and their niche in the automotive

world.

How Rotary (Wankel) Engines Work

Unlike conventional engines that use pistons to convert fuel

into mechanical energy, rotary engines rely on a triangular rotor that spins

inside an oval-shaped housing. This design allows for a continuous combustion

cycle with fewer moving parts. The key components include:

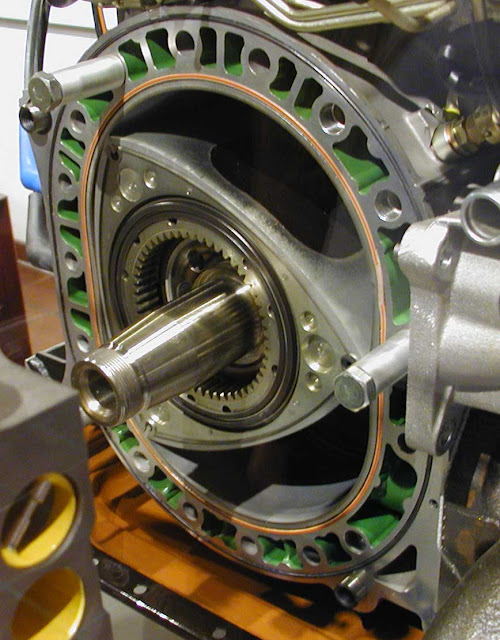

Rotor:

A triangular-shaped component with curved sides that rotates

inside the housing.

Each corner of the rotor acts as a combustion chamber.

Housing:

An oval-shaped chamber where the rotor spins.

Contains intake and exhaust ports as well as spark plugs for

ignition.

Eccentric Shaft:

Converts the rotational motion of the rotor into usable

mechanical energy.

The combustion process in a rotary engine can be summarized

in four stages:

Intake: The rotor draws in the air-fuel mixture through the

intake port.

Compression: The mixture is compressed as the rotor moves.

Combustion: The spark plug ignites the compressed mixture,

driving the rotor forward.

Exhaust: The burnt gases are expelled through the exhaust

port.

This continuous motion results in smoother operation

compared to the up-and-down motion of pistons in traditional engines.

Advantages of Rotary (Wankel) Engines

Compact and Lightweight:

The simple design allows for a smaller and lighter engine

compared to piston engines with similar power output.

High Power-to-Weight Ratio:

Rotary engines deliver impressive power relative to their

size, making them ideal for performance-oriented vehicles.

Smooth Operation:

The absence of reciprocating motion eliminates vibration,

resulting in a smoother driving experience.

Fewer Moving Parts:

With no valves or camshafts, rotary engines have fewer

components that can wear out, potentially reducing maintenance.

High RPM Capability:

Rotary engines can achieve high revolutions per minute

(RPM), contributing to their sporty character.

Challenges of Rotary (Wankel) Engines

Fuel Efficiency:

Rotary engines are less fuel-efficient compared to piston

engines, as they often consume more fuel for the same power output.

Emissions:

The design can lead to incomplete combustion, resulting in

higher emissions.

Durability:

The apex seals on the rotor, which maintain compression, are

prone to wear and require regular maintenance.

Oil Consumption:

Rotary engines typically consume more oil due to their

design, which uses oil to lubricate the apex seals.

Limited Application:

The niche design has limited widespread adoption,

restricting its use to specific vehicles and enthusiasts.

Applications of Rotary Engines

Rotary engines have been used in various applications over

the years, including:

Sports Cars: Mazda is the most prominent manufacturer of

rotary engines, famously using them in vehicles like the RX-7 and RX-8.

Aviation: Rotary engines’ lightweight design makes them

suitable for light aircraft.

Motorcycles: Companies like Suzuki have experimented with

rotary-powered motorcycles.

The Future of Rotary Engines

While rotary engines have become less common due to their

fuel efficiency and emissions challenges, they are not entirely obsolete.

Manufacturers like Mazda are exploring ways to modernize rotary technology,

including its use as a range extender for electric vehicles. Advances in

materials and engineering could address durability and efficiency issues,

giving rotary engines a new lease on life.

Conclusion

Rotary (Wankel) engines are a fascinating example of

innovative engineering, offering unique advantages and challenges. Though not

as widely adopted as piston engines, they have carved out a niche in the

automotive and aviation industries. As technology continues to evolve, rotary

engines may yet find renewed relevance in a world increasingly focused on

efficiency and sustainability.

Comments

Post a Comment